The successful completion of form, fit, and function testing for Lenexa-based Enduralock’s OneLink satellite docking connector marks a critical leap forward for the hardware, said Dr. Harold Hess — earning his Kansas City-built technology a ticket aboard future space launches.

“By proving the hardware’s soft docking and self-alignment capabilities work in a simulated zero-gravity environment, the team has confirmed the reliability of the mechanical latching and alignment systems essential for future on-orbit operations,” the Enduralock CEO said this week via a company press release.

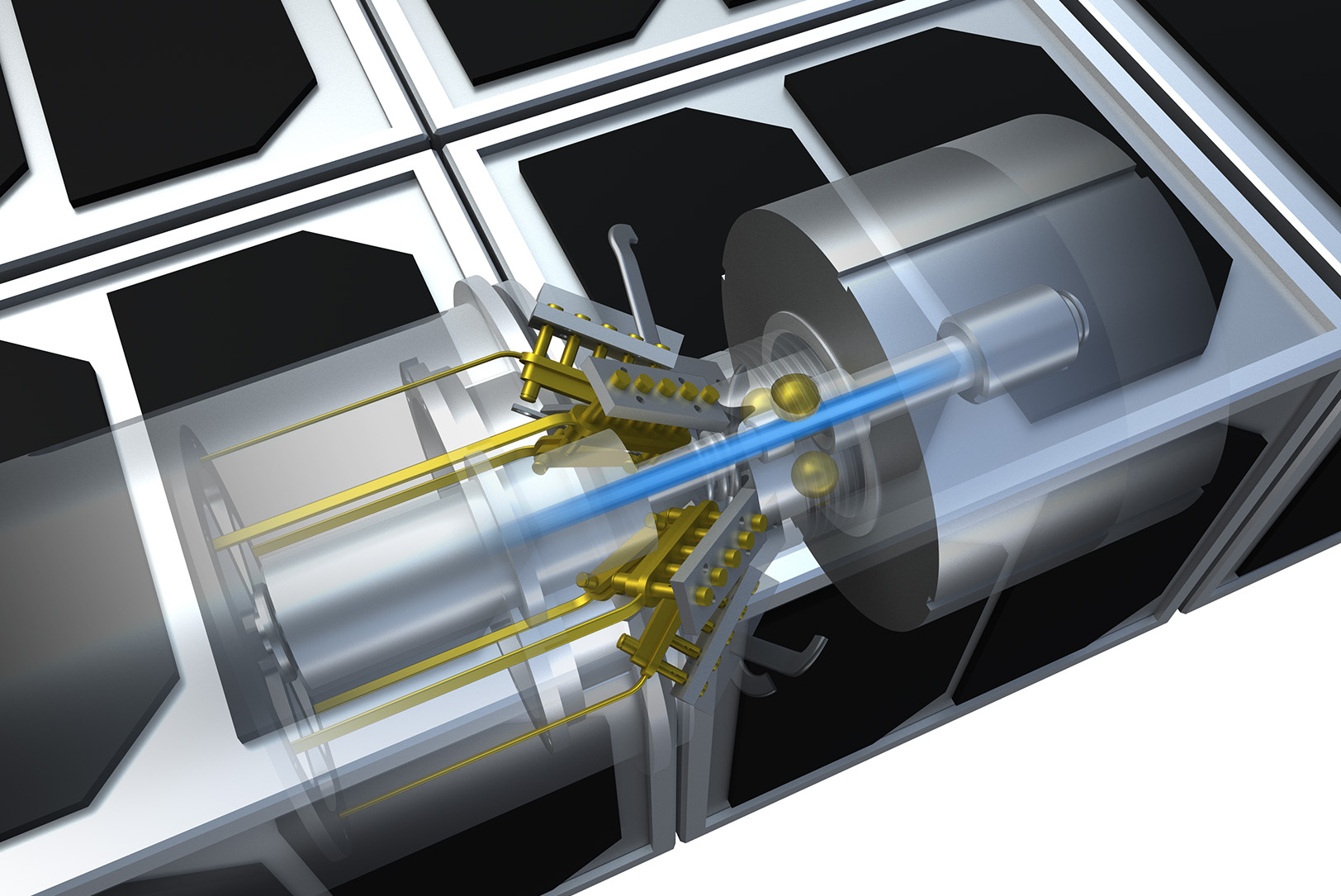

During the test campaign at Arkisys’ 1G robotic ground test facility for In space Servicing, Assembly, and Manufacturing (ISAM), a prototype of the female half of Enduralock’s OneLink connector was mounted on an Arkisys Port prototype, while the male half was mounted on a robotic arm provided by Motiv Space Systems to simulate a zero-gravity environment on orbit.

Enduralock’s OneLink satellite docking hardware undergoes form, fit, and function testing in a zero-gravity environment; photo courtesy of Enduralock

Hess noted that seeing the OneLink halves successfully self-align and soft dock gives the team high confidence in the design. The testing successfully validated OneLink’s ability to manage off-nominal approaches, compensating for both angular and radial misalignment to achieve a secure soft dock, he said.

Harold Hess, co-founder and CEO, and Diana Greenberg, co-founder and COO, Enduralock; courtesy photo

This technical success opens the door for Enduralock to be included on future Arkisys launches. The male half of OneLink is scheduled to launch onboard the first Arkisys Cutter satellite in early 2027. Subsequently, the female half will launch onboard the first Arkisys Port Module in mid-2028.

ICYMI: KC’s Enduralock secures $1.25M SpaceWERX contract to boost satellite docking tech

Integrating OneLink onto these missions supports the vision of a reconfigurable, standardized interface that allows customers to integrate payloads quickly and securely.

Dave Barnhart, CEO of Arkisys, emphasized that the Arkisys Port is designed as a scalable business platform in orbit, one that depends on robust logistics and reliable connection standards to enable growth.

“Arkisys is committed to building partnerships that deliver the key technologies required for the expanding in-space servicing, assembly, and manufacturing (ISAM) market,” Barnhart said. “Physical, standardized connections are the backbone of a thriving orbital economy, enabling refueling, in-space assembly, and cargo movement between spacecraft to establish a sustainable manufacturing base in orbit.”