TOPEKA — Regularly confronted with a lack of supply in the housing market — and the subsequent higher prices — landlord and general capital investor Chris Stemler faced a multi-dimensional challenge.

“I thought to myself, ‘How do I help solve an inventory problem?’ the Topeka-based Trident Homes founder said.

“I know I’ve got renters who need more availability and affordability,” he continued. “There’s not enough housing and I know there’s a need for it, so what do I do?”

That problem — and Stemler’s search for a scalable solution — led him to concrete 3D printing.

By late summer or early fall, Trident plans to be printing full-scale homes directly on lots and larger land parcels across eastern Kansas — bringing to market an option that’s faster to build and significantly more affordable than traditional homes.

They’re also more fire resilient and durable enough to withstand winds from an F4 tornado.

Trident’s first full-scale machine is waiting for Stemler in Utah.

“Our next step: Our crew needs to go up to Utah between now and July 3 and train on our equipment,” he explained. “Then, we’ll come back with that printer and, after Independence Day, we’re going to start working on some infrastructure projects — some for the company, some contractual for other parties — because we have to print some structures in order to comply with our training and contract with our print manufacturer.

The goal: deliver affordable, durable, customizable housing erected fast enough to help alleviate a persistent inventory crisis.

“To give you some specifics, Shawnee County, where Topeka is, is 175,000 people. Normally we should see 300 to 400 houses on the market at any given time,” said Darin Stephens, CEO of Stone & Story Real Estate Group, which houses the headquarters of Trident Homes.

Stone & Story has partnered with Trident Homes to bring its 3D-printed homes to market.

Illustrating just how dire the housing crisis has gotten, Stephens said, “This week, we’ve got 168 houses on the market that are active at any given time, and that’s every price range for the county for 175,000 people.”

When a person targets homes in the $150,000 to $250,000 range, only about 35 of those 168 are available, he added.

And, the need isn’t just in Topeka.

“It crosses over to Lawrence, Kansas City, Eastern Kansas,” Stephens said. “We’ve got this need across the board.”

Faster, tougher, but still home

By using concrete instead of lumber, Stemler said, Trident gains several advantages: end product resilience, efficiency and cost savings.

The homes are printed under a climate-controlled tent on-site, a process that can reduce wall construction time from weeks to days. Once cured, those walls are far more durable than drywall — an attractive prospect for landlords and long-term homeowners alike.

“You can have a rental, you go through a year lease, and you’re going back in and you’re putting Humpty Dumpty back together again,” Stephens said. “With this structure, with this type of technology, that’s going to minimize that because it’s a little hard to destroy a concrete wall versus sheetrock or whatever.”

Stemler anticipated consumer skepticism of the product, especially from within a market not known for rapid adoption, he said. But feedback from Trident’s first open house challenged that assumption.

“I expected some of our open house to be just people curious about the process and that’s really not who showed up,” Stemler said. “It was a lot of individuals who were actively considering something like this as an option.

“I also think that Topeka — and this happens not because people mean to — but just generally Topeka gets compared to Lawrence or Kansas City almost as if it’s a backwater, and that’s not really the case,” Stemler added. “Fifteen percent of any population would generally be considered early adopters… and that’s true whether you’re in Kansas City, you’re in Topeka, you’re in Wichita, you’re in Lawrence.”

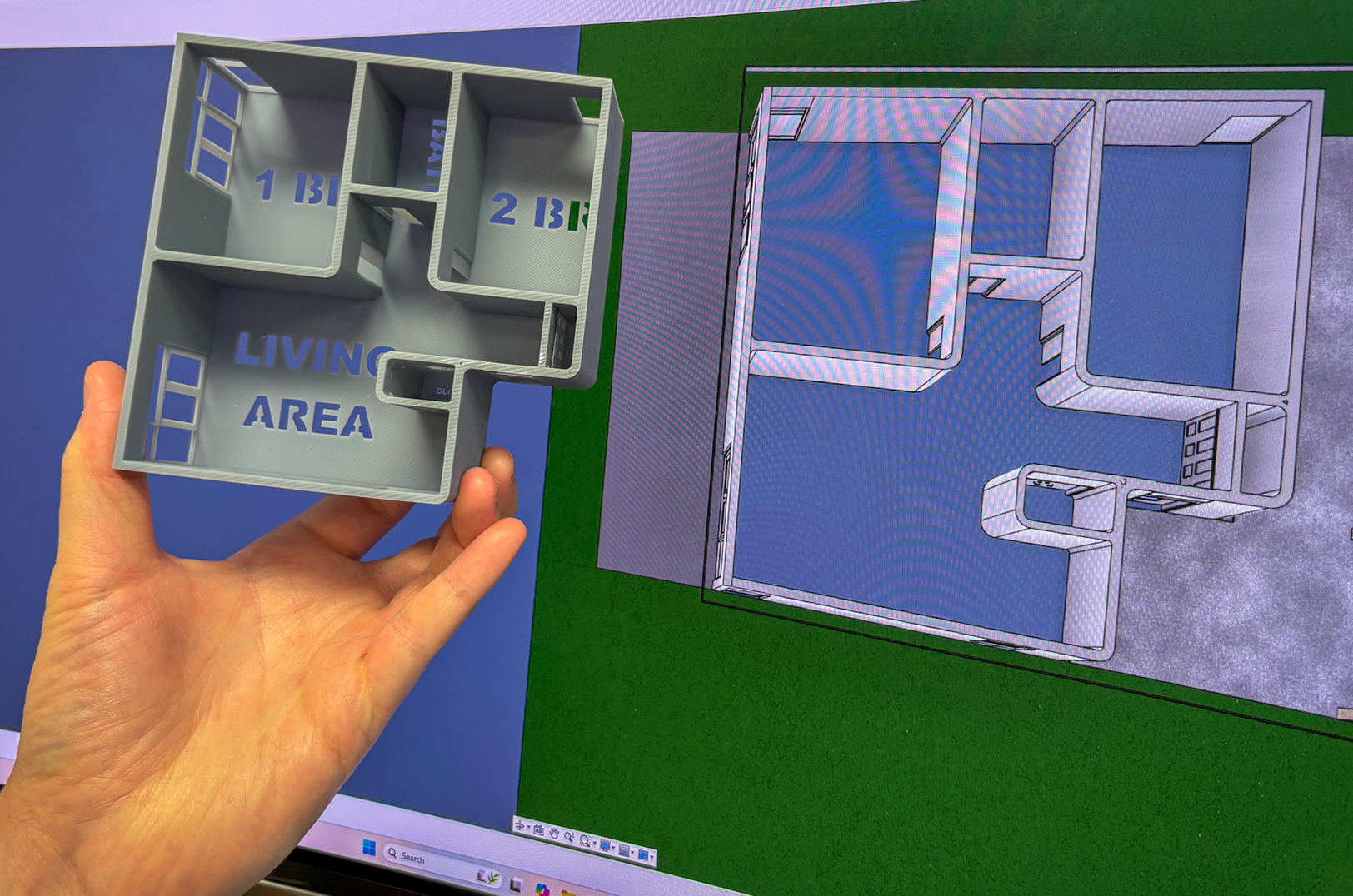

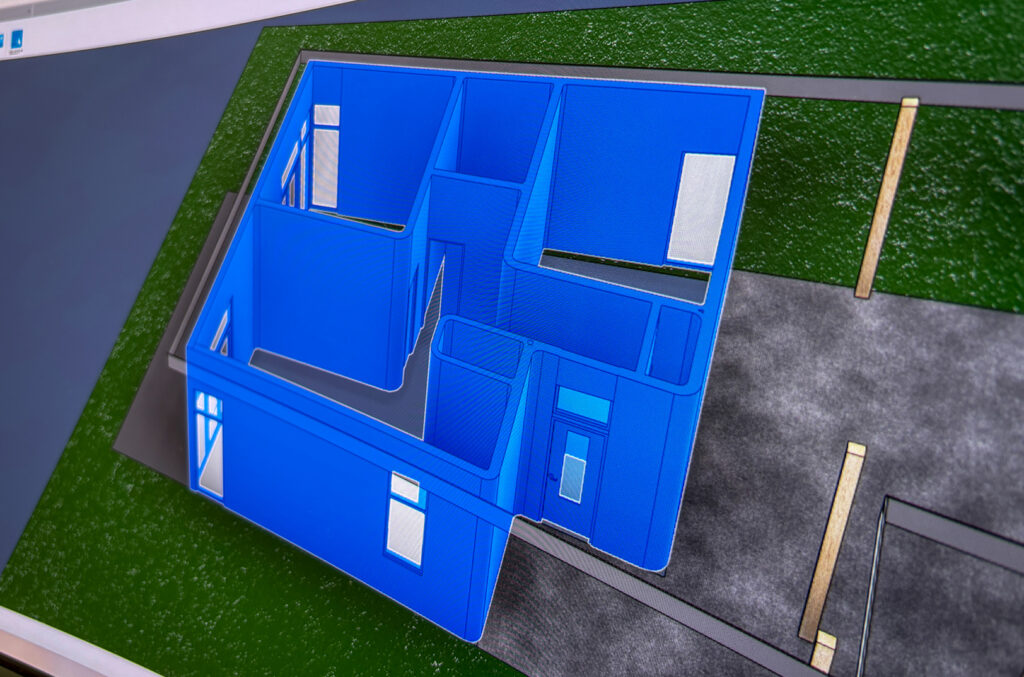

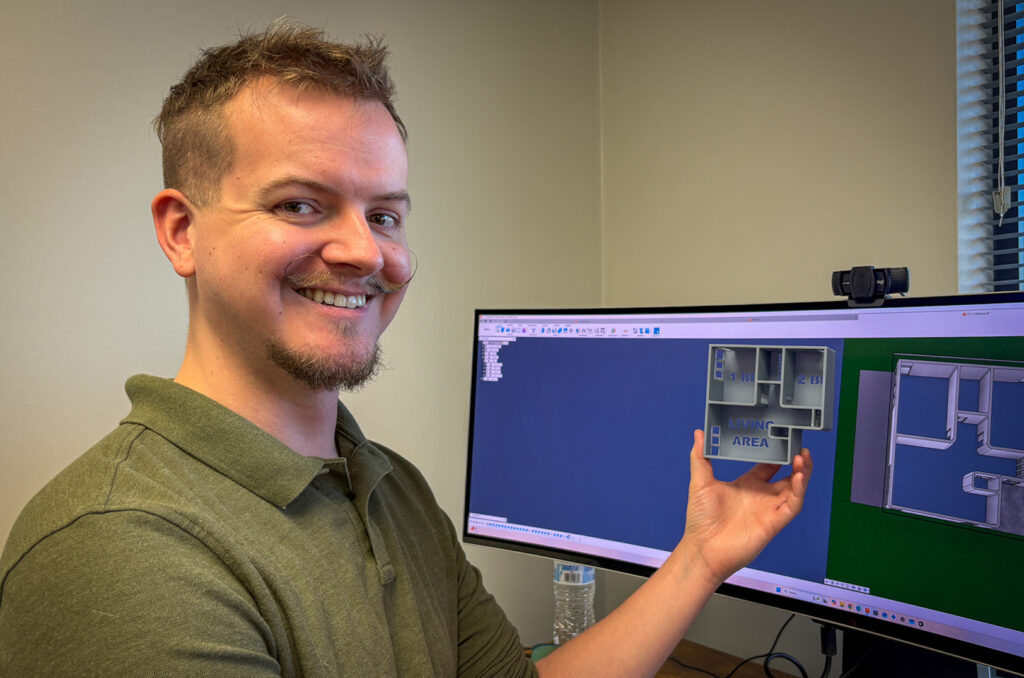

Scott Smith, 3D design technician for Trident Homes, illustrates the company’s technology with a model and diagrams of the structure; photo by Haines Eason

Stick-built, concrete-printed

If Stemler is the visionary and Stephens the strategist, Scott Smith serves as the bridge between idea and implementation.

“There’s this association with 3D printing — that it makes these cheap little plastic toys, and that’s definitely not what we’re doing,” said Smith, 3D design technician for Trident Homes.

“As you know, the printer that we’re going to end up running actually prints with concrete… (And the result) is a real home,” he continued. “It’s just made in a slightly different way and in a way that allows us to really control a lot more of the process.”

Much of the cost savings come from speed and materials used, Smith said.

“What a framing crew might be able to do in one to two weeks, we can do in one to two days. So that is a huge time and labor savings right there,” he said. “But also the materials are just cheaper.”

In contrast to misconceptions based on large-scale, commercial projects, walls within Trident Homes aren’t solid slabs, Smith added.

“The 3D printer actually will print primarily two walls,” he said. “There’s an exterior and an interior. … But you do end up with a wall cavity, and so there are spaces for your utilities and for your insulation.”

That space makes rough-ins easier during construction and also allows for maintenance later on, Smith said, acknowledging he’s seen such avoidable pain points firsthand.

“I did quite a bit of handyman work down in Florida where all the houses are poured concrete and/or cinderblock construction,” he said. “It was just frustrating trying to do anything there — as someone who’s had to tell homeowners they needed to rip up a slab to fix a leak, that matters to me.”

He also sees long-term potential in the design flexibility offered by 3D printing.

“Traditional concrete construction is limited by formwork,” Smith said. “We’re not. That opens up new geometry, new possibilities. Right now, we’re focused on affordability. But once we’re established, who knows? We can get weird with it.”

Bringing a concierge experience

Even with new materials and methods, Trident’s founders are focused on delivering something that might be the most novel thing of all, the said: a home-buying experience that’s grounded in service.

“When we sit down with the buyer and the design team,” Stephens said, “some of our first conversations are going to be, ‘Tell us how you like to live. Tell us about you. Tell us what’s important to you.’”

“We’re not ‘Here, just take the number.’ It’s not all about the numbers; it’s not all about the transaction,” he continued. “We’re here for them.”

It has to be a win-win for everybody, Stephens emphasized.

“And part of that win-win is bringing the journey to full fruition with the buyer so that they feel like, ‘I’ve enjoyed this process, I like it. And at the end, I’m getting an amazing beautiful home,’” he said.

Haines Eason is the owner of startup content marketing agency Freelance Kansas. Previously he worked as a managing editor for a corporate content marketing team and as a communications professional at KU. His work has appeared in publications like The Guardian, Eater and KANSAS! Magazine among others. Learn about him and Freelance Kansas on LinkedIn.

This story is made possible by eGrowth Ventures.

eGrowth Ventures (EGV) is a business unit of NetWork Kansas supporting innovative, high-growth entrepreneurs in the State of Kansas. NetWork Kansas promotes an entrepreneurial environment by connecting entrepreneurs and small business owners with the expertise, education and economic resources they need to succeed.