A KCK startup that could revolutionize space transportation is among 14 companies selected this week for an accelerator program from Amazon Web Services that focus on “transforming the future of space for all of humanity.”

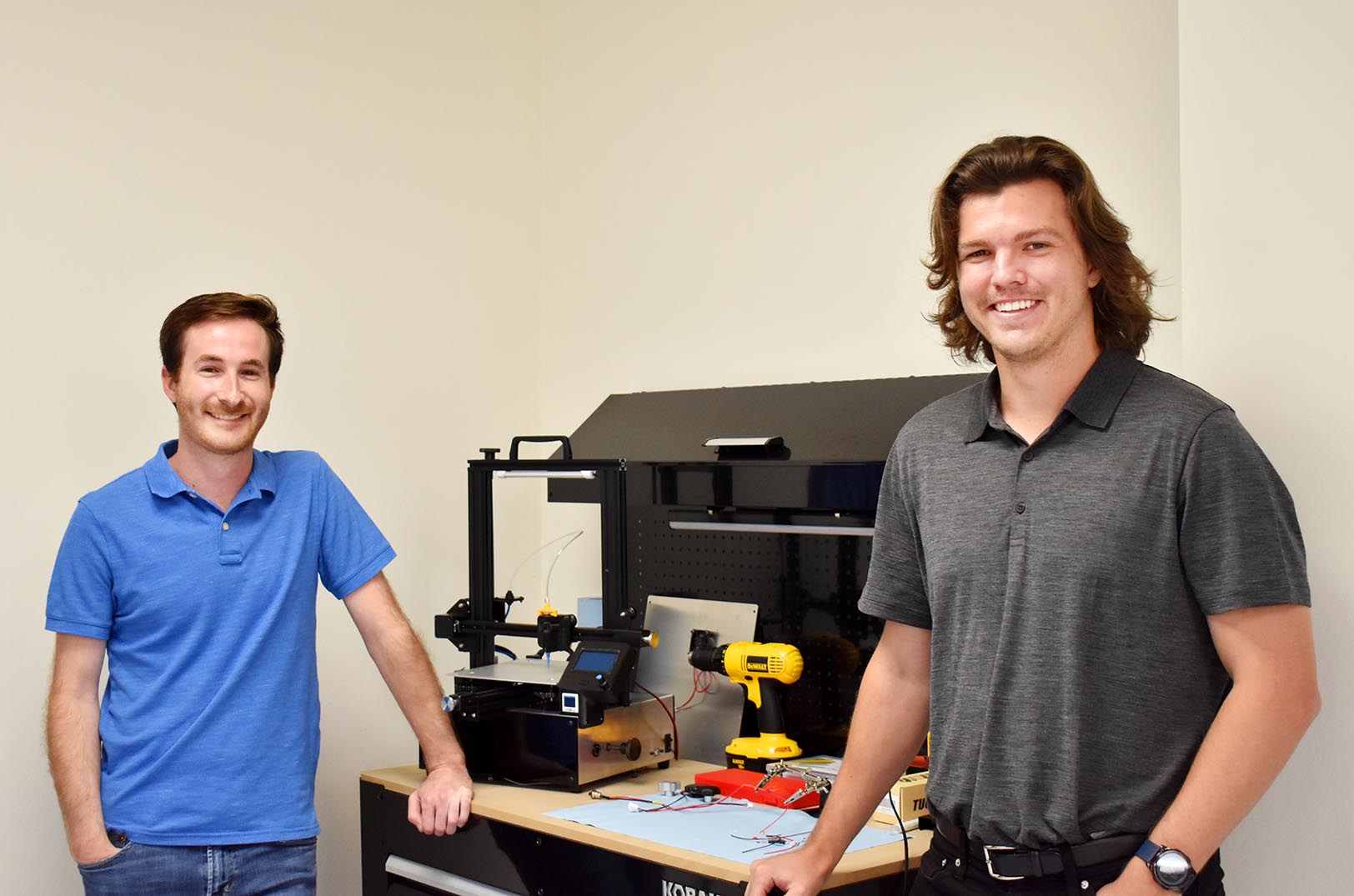

Kansas City-based Raven Space Systems — led by co-founders Ryan Cowdrey and Blake Herren — is building entirely 3D printed reentry capsules for on-demand cargo return from space. The company’s automated factory is expected to enable cheaper and faster capsule production with adaptability for any mission.

“While our innovation is a platform technology capable of 3D printing several composite materials for the first time, we recognize the value of focusing the development of this innovation to address a specific and high-impact problem,” Herren told Startland News. “Raven has de-risked the technology with our nondilutive funding and there is no science left to be done.”

“Engineering, scaling up our systems, and proving our 3D printed materials are our next steps,” he continued. “Therefore, Raven has started raising a seed round to fund the development of our industrial 3D printer and validate the performance of our 3D printed heat shield at scale with assistance from NASA.”

The 2023 AWS Space Accelerator — a technical, business, and mentorship program to help startups advance their space solutions and accelerate their growth using the cloud — is expected to help Raven on that journey.

AWS Space Accelerator participants receive business development and strategy support, specialized AWS training, mentoring from AWS space domain and technical subject matter experts, up to $100,000 in AWS Promotional Credit through AWS Activate, and support on building and scaling their solution worldwide. The curriculum also provides opportunities to work with AWS customers and AWS Partner Network (APN) Partners looking for innovative space solutions.

“From 3D-printed space vehicles to orbital robots, satellite solutions built on artificial intelligence (AI), and space-based initiatives that can help us better use Earth’s valuable resources, these emerging startups are leveraging AWS as they develop the next generation of exciting space technology,” AWS said of the 14 companies selected for the new cohort.

Click here to learn more about the other ventures selected for the 2023 program.

AWS Space Accelerator 2023 cohort members and the AWS Venture Capital (VC) and Startups teams; photo courtesy of AWS Space Accelerator

The AWS Space Accelerator is expected to help these startups leverage flexible, agile cloud tools that can help power their space missions and innovate faster — all to support a safe, prosperous, and sustainable future in space, according to AWS.

Raven Space Systems was originally founded as Raven 3D Printing in June 2020 with the mission of establishing a new era of manufacturing through 3D printing the highest quality polymers and composites. Cowdrey and Herren met while students at OU, later relocating to Kansas City during the pandemic.

Click here to read more about Raven’s origins and its co-founders’ arrival.

Ryan Cowdrey and Blake Herren, Raven Space Systems

“When we moved to KC, we had a very early-stage proof of concept 3D printing innovation,” Herren said. “We didn’t know what it was truly capable of. But we knew we were onto something when NASA and the Air Force awarded us $1 million in STTR contracts when our only 3D printed sample had been a small rubber cone.”

In the past year, Raven developed composite material formulations for our patent-pending manufacturing process to 3D print aerospace-grade thermoset composite materials at scale for the first time, he added.

“We are developing large-scale 3D printing of structures as strong as aluminum at half the weight and heat shields with higher performance than the state-of-the-art,” Raven said. “While developing this revolutionary innovation, we discovered a growing need in the space industry to increase the frequency and lower the cost of returning cargo from space.”

While competitors were starting to emerge in this field, Raven’s co-founders recognized no one was improving the production of reentry vehicles, he explained.

“We determined that 3D printing entire reentry capsules with our novel technology will enable us to build an automated factory to manufacture capsules 10-times faster at 95 percent lower cost with a software-driven approach enabling adaptability for any mission,” Herren said.

Click here to read more about Raven’s on-demand space capsule return technology.