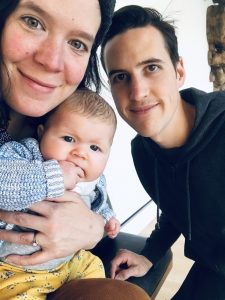

Living as determined “plastic haters,” the husband-and-wife duo behind Detour Goods craft wooden toys as a callback to higher-quality manufacturing and a time before entertainment was dominated by technology.

“I think we’re living in a day and age where we’re just so addicted and connected to our screens,” said Jordan EuDaly, co-owner of the Kansas City-based toy goods brand created by her husband, Brent. “My personal life goal is for us to create really interesting things that can engage kids and families with each other, instead of engaging with the screen.”

Detour Goods actively practices intentional sustainability throughout the manufacturing process while still maintaining the look and feel of quality, handcrafted products, added Brent.

Click here to shop Detour Goods.

“[Plastic is] just not our style — especially when it comes to toys, Brent said, laughing. “There are just some really obnoxious, ugly toys out there.”

“I could make it work using cheaper materials, but the way these products go together — and come apart and go back together with magnets — just has a really satisfying, powerful feel,” he added, noting a series of wooden dinosaurs serve as the top sellers of the brand.

Detour Goods follows Brent’s 2017 exited startup, Elastic Precision Manufacturing, which sold novel, wooden rubber band guns as toys to “‘desktop-based millennials,” he said.

“That was my step from architectural woodwork and cabinetry into the woodworking realm of jumping into toys, and [after Elastic Precision sold] we both found ourselves between things … so we basically took a year and did some overseas travel,” he added. “I guess that’s where the word ‘detour’ comes from.”

Detour Goods

In coming back to KC, the couple set up a new home with a workspace for their new company. Brent gravitated once again to using wood — not only because of his experience in the medium, but because of the creativity of design that is required when making intricate wooden pieces, he said.

“It really just starts in the woodshop, with a block of wood, and just staring at it thinking, ‘Hey, I think it’d be kind of cool to make a dinosaur,’” Brent said. “But part of the reasoning that I really like is taking this heavy, traditional material and making things that were not traditionally made out of [wood.]”

“[Wood] can be kind of a tricky material to work with when you’re making slightly more complicated products. It just doesn’t lend itself to just crazy complex designs like plastic does,” he added. “The limitations on what you can make out of wood are just a little bit more restrictive.”

The pair collect lumber from a relative’s 130 acre property in the Kansas City area but rarely cut down any trees to avoid unnecessary environmental impact, Brent said.

“A lot of times, they’re just windfalls or storm damage or trees that have just reached their natural life and have expired so usually once a year, I spend a few weekends just running around through the woods with a tractor and haul logs around,” Brent said. “It’s a lot of hard physical labor and a lot of work, but it’s really rewarding; just kind of go through that whole process starting with a tree and taking it all the way to a finished product.”

Most customers don’t understand the effort and energy that her husband expends in his one-man woodshop, Jordan said.

“It’s so fun to watch him go on this inventor journey because it feels like grade school science class all over again,” she laughed. “It feels like one big science project because he’s problem solving and prototyping and troubleshooting and trying to figure out just how to get his ideas to tangible product.”

“A lot of people don’t realize they’re just seeing the end product — not the hundreds of hours behind the scenes of ideating, making something better, and prototyping over and over,” she added.

Balancing eco-friendliness in company policy as well as personal life, Jordan noted. As new parents, the duo, admittedly, have some needed plastic items, though they aspire to function as sustainably as possible.

“We lived in New Zealand for six months, a couple of years ago … It really gave us a lot of inspiration that we took back with us, and so now we rent, hatch, and raise our own quail and we eat the eggs from them,” she said. “[Brent’s] also planted a garden in our little plot here and we’re composting. So, I think we’re making steps.”

“We’re not that extreme…. We’re just trying to run a small industrial operation out of our home,” Brent joked. “I think we’re just a little more pragmatic about it. Sometimes the best way to save money is to be environmentally friendly and be aware of the waste you’re generating and where it goes and try to make sure it’s all responsible.”

Officially launched in October 2019, the company has been focused on working craft fair circuits to drive business to its online store, Brent and Jordan said, noting the toys were so popular at the Strawberry Swing Holiday Fair that their inventory was completely cleaned out.

“Eventually the goal is to find products that have more potential than what we can do out of the one-man woodshop operation — so outsourcing production somewhere to expand our production capacity [is an option],” Brent said.

Jordan hopes to jump into the creative process as well in 2020, she said, noting she also is an artist and painter.

“Having a little child has definitely encouraged my creativity and I love the idea of creating products that connect family to one another,” she said.

“I would say, [our] short term goal: Just make products and have fun doing it,” Brent added.